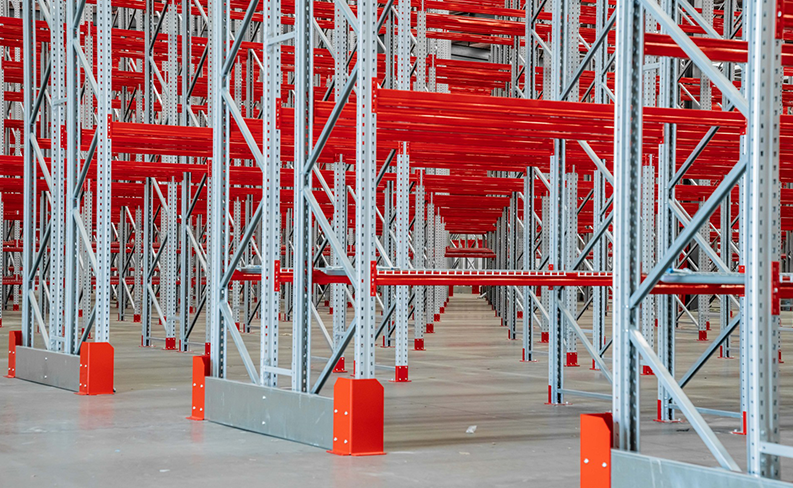

Warehouse Design and Layout

The efficiency and storage capacity of any warehouse operation is dependent on its design and layout. Whether your company is in manufacturing or assembly, order fulfilment and shipping, a sound warehouse floor plan and design using all airspace will assist you to minimise costs and maximise productivity.

Planning your warehouse layout is a crucial process, as it directly impacts the efficiency and productivity. A well-planned layout should arrange the processes in a logical sequence to streamline your operations, reduce expenses, and boost productivity.

A well-designed warehouse layout will provide easy access to stored goods, minimise movement and travel time and improve order fulfilment rates.

Taking the time to consider all your business requirements during the planning phase is a sound investment and can minimise additional costs at a later stage. The effort to alter a planned layout once the construction starts can be quite costly.

To design an efficient and streamlined operational layout, consider the following factors:

It is crucial to assess all your business requirements and review associated budgets before commencing the design and layout process as there may be design options that are more comprehensive and potentially more expensive. It is important that you consider the most suitable and cost-efficient solution for your warehouse so that any potential additional costs can be recouped by a productive layout.

The uninterrupted flow of goods, employees and materials handling equipment is vital in the layout to facilitate the smooth functioning of your warehouse. You can avoid inefficient paths and disruptions by carefully planning your warehouse design and layout, enabling each operational step to occur sequentially.

During the warehouse design and layout phase, it’s essential to ensure easy accessibility to all areas and different types of products within your facility. The layout should make it easy for employees to navigate throughout the facility, locating and picking items without moving other products. This will directly increase your productivity and order fulfilment rate.

The input and output of a warehouse, or throughput, considers the number of products managed through various warehouse processes. This includes receiving goods, put away, product storage requirements, picking and packing and shipping. By analysing this data, a warehouse design and layout can be produced with an efficient flow of goods and accommodates your warehouse equipment.

Knowing the number of people required to manage the throughput of a warehouse directly affects cost management. A well-designed warehouse will assist you in understanding skill requirements and training of employees to operate efficiently in a new facility. The warehouse design and layout will also consider the safety of all personnel working in the operational space.

Warehouse design and layout incorporates the relevant authority guidelines for your facility. Abiding by these guidelines ensures the safety of your employees, equipment or other valuable assets, as well as assisting you to avoid fines and problems.

Bowen Storage design and layout services ensure the optimal utilisation of your operation and facility. We design your warehouse using a combination of pallet racking system solutions that optimise warehouse space, boost productivity and improve inventory management.