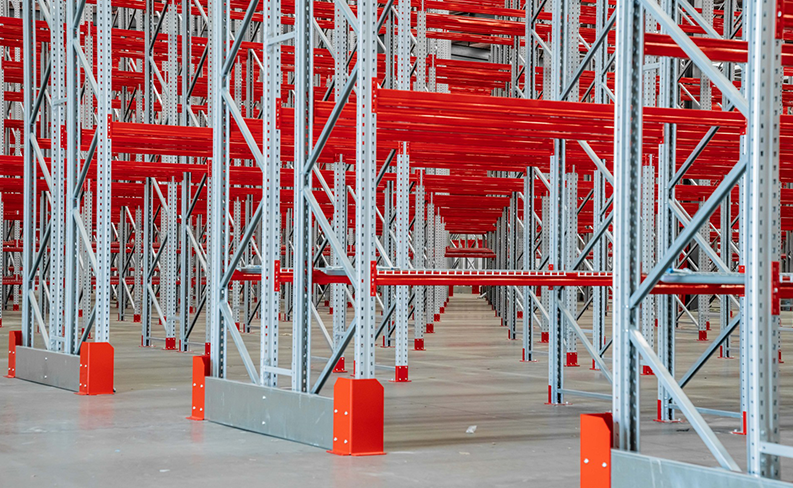

Satellite Pallet Racking systems improve operational productivity as warehouse staff are not spending their time moving pallets into place. It is also a great option for high-density storage in operations with limited staffing levels.

Satellite Pallet Racking, also known as shuttle racking, is designed for deep lane pallet storage. The pallet shuttle system can be used either as a first-in-first-out (FIFO) or last-in-first-out (LIFO) system as it has the capability to both take the pallets back or retrieve them.

The Satellite Pallet Racking system ensures a more efficient and high-density storage environment, maximising your available floor space and storage capacity. It optimises the storing, loading and retrieving SKU’s with high-density stock levels. In addition, it is highly adaptable to most pallet sizes.

The racking is similar in style to drive-in racking; however, each level can be a separate SKU. It operates by a shuttle cart being placed on rails under the pallet rails. The shuttle then travels into the rack and rises to raise the pallet and bring it back to the front of the rack.

The remote-controlled pallet shuttle is a self-powered device that runs on rails in the storage channels for retrieving pallets. The system carries goods in and out of deep storage tunnels without any human intervention. It is an excellent solution for long term or dense storage of a large number of pallets using a minimal building footprint. Using this automation solution delivers low running costs but does require highly efficient warehouse management.

The system can be relocated within the warehouse using a standard forklift truck, delivering further reduced operating its cost-efficiency.

The system has strong frame bracing, and the uprights are available in a range of widths, depths and thicknesses. There are racking end protection for safe operation along with front and rear upright protectors for minimising damage and lowering the risk of accidents.

The Satellite Pallet Racking System is a state-of-the-art storage solution that optimises warehouse space and staff efficiencies and productivity in a semi-automated warehouse environment.